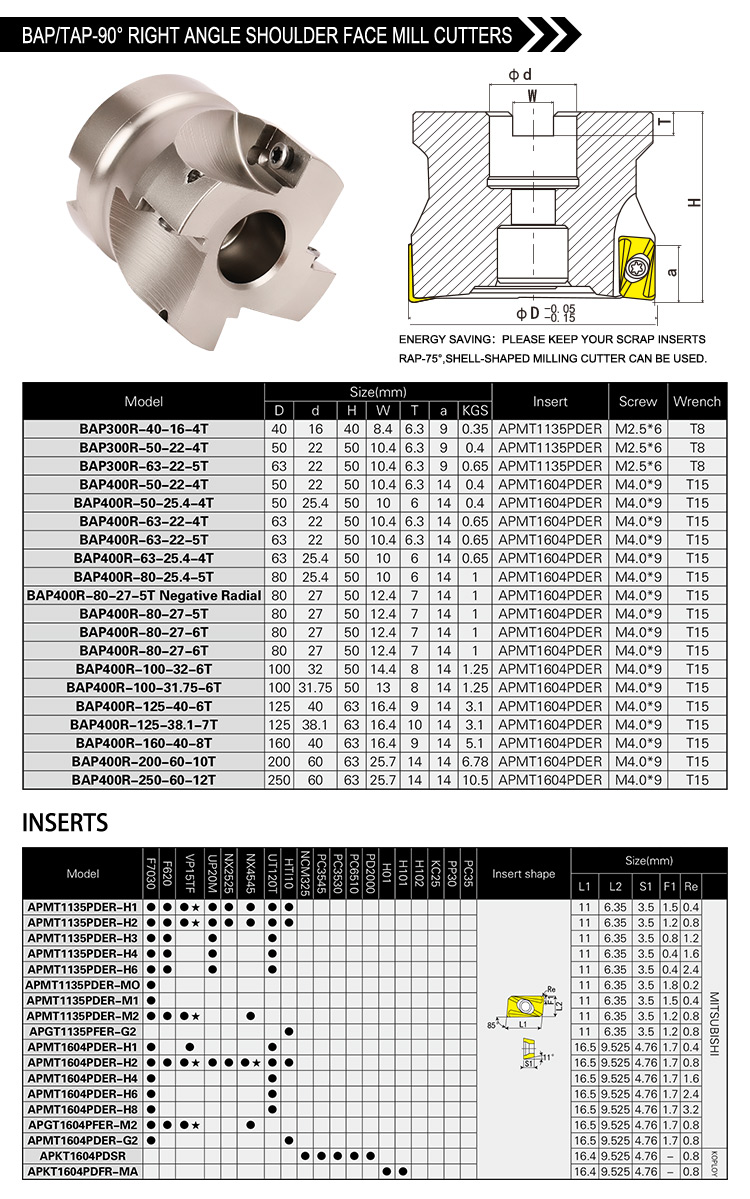

- PARAMETERS

- VEDIOS

Milling Tool BAP-90°Face Milling Cutter

Material: 42CrMo

Hardness: 40-43hrc

Overall pre hardening, and then fine machining to improve the machining accuracy Check that the clearance between the blade and the milling cutter body is less than 0.02 with a feeler gauge. When the blade is used up in the axial and radial directions ≤ 0.03, reduce the surface roughness and prolong the service life of the tool.

Cryogenic treatment: all CNC milling cutters and face milling cutters are subject to ultra long cold treatment (- more than 20 hours above 180 ° C) to improve the hardness, toughness and durability of tools and reduce residual internal stress.