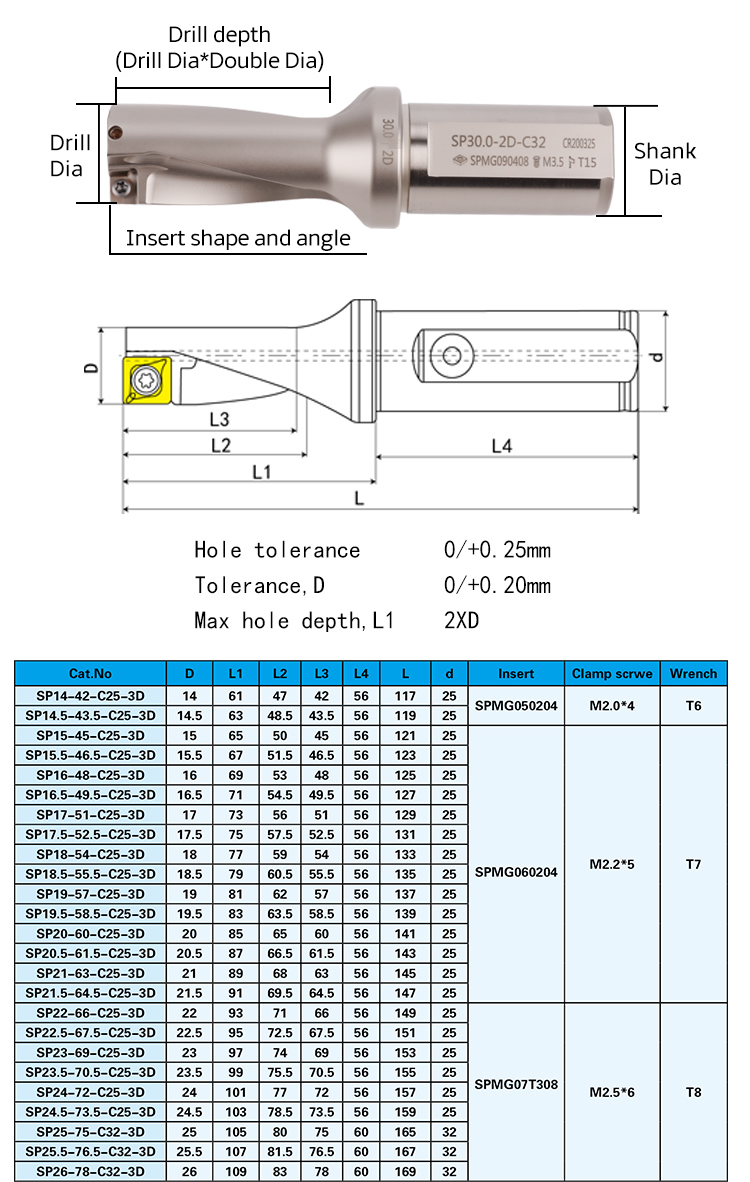

- PARAMETERS

- VEDIOS

Fast drill, also called U drill, is a kind of internal cold drilling, row cutting good, high efficiency, can be continuous drilling.

1. Processing efficiency is generally 2-3 times that of twist drill.

2.U-drill can be directly processed on the workpiece without the need of center drilling guide hole.

3. The front of the tool body is equipped with replaceable blades, which reduces the cost of use.

4. The difference between U-drill and ordinary drill is that U-drill uses inserts ----- peripheral and center inserts, no need to re-sharpen the tool when it is worn out to directly replace the inserts, the use of indexable inserts saves material than the overall hard drilling and the consistency of the inserts makes it easier to control the size of the parts.

5.The rigidity of U-drill is good, it can adopt high feed rate, and the machining diameter of U-drill is much bigger than common drill, the maximum can reach D50~60mm, of course, U-drill can't be made too small due to the characteristics of mounted insert, U-drill below D10mm is rare.

6. U-drill encountered a variety of materials only need to replace the same type of different grades of inserts can be, hard drilling is very convenient.

1. Processing efficiency is generally 2-3 times that of twist drill.

2.U-drill can be directly processed on the workpiece without the need of center drilling guide hole.

3. The front of the tool body is equipped with replaceable blades, which reduces the cost of use.

4. The difference between U-drill and ordinary drill is that U-drill uses inserts ----- peripheral and center inserts, no need to re-sharpen the tool when it is worn out to directly replace the inserts, the use of indexable inserts saves material than the overall hard drilling and the consistency of the inserts makes it easier to control the size of the parts.

5.The rigidity of U-drill is good, it can adopt high feed rate, and the machining diameter of U-drill is much bigger than common drill, the maximum can reach D50~60mm, of course, U-drill can't be made too small due to the characteristics of mounted insert, U-drill below D10mm is rare.

6. U-drill encountered a variety of materials only need to replace the same type of different grades of inserts can be, hard drilling is very convenient.